Dynamics of Rotating Machinery

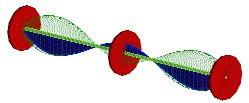

The discipline of dynamics of rotating machinery (rotor dynamics) refers to systems where at least one part rotates with a significant angular momentum. This discipline is applied to analyze the behavior of freely rotating objects as well as constrained (by bearings) ones.

![]() Sylabus

Sylabus

Course topics

- Introduction, review and examples for the role of a microprocessor in new products.

- Programming the microprocessor (microcontroller) to handle electromechanical products incorporating sensors.

- Methods for interfacing the real world performing and input/ output: Polling and interrupts.

- Sensors actuators, design of integrated systems.

- Laboratory exercises on a real system controlled by a micro-computer (TMS320F240), motors, actuators, sensors.

- Programming the laboratory system using Assembly & C languages.

- Creating a man-machine interface, transferring data and commands to/from the system in real-time.

Grade Composition

- Introductory exercise – 3%

- 4 labs assignments – 40%

- 4 quizes – 32%

- Final Project – 25%

- Intoduction

- Review of vibration theory 1-DOF, N-DOF

- free vibration, forced vibration, mode shapes, modal decomposition / superposition, orthogonality, Lagrange equations.

- Jeffcot rotor

- 1 DOF rotating shaft + disk, complex notation, stationary and rotating coordinates

free response – eigenvalues, forward/backward whirl, unbalance – forced response, asymmetric supports, Campbell diagram, internal damping vs. external damping – stability, acceleration through critical speeds, Continuous systems - Torsional vibration

- Continuous Models, limitations

- Discrete Models – simple FE model

- Coupled systems, connected shafts

- Interference diagram – engine orders

- Shaft bending vibration

- Euler/Timoshenko beam

- Kinetic and potential energy of a rotating shaft

- Shaft with rigid disks and flexible supports

- Gyroscopic effects

- Continuous systems

- Flexible disks

- Forward/backward whirl

- Campbell diagram, measurements interpretation

- Static loads, synchronous loads

- Experimental verification

- Critical speeds

- Natural frequencies and modeshapes

- Unbalance response & balancing

- Measurements and signal processing

- Experimental identification, bearings, shaft, damping

Grade Composition

- Home Assignments – 35%

- Quiz-25%

- Final Project – 40%

Reference books

General vibration

- Meirovitch, Leonard, Fundamentals of vibrations / Leonar c2001. (2226350)

- Meirovitch, Leonard — 2nd ed. Elements of vibration analysis / Le c1986. (2006363)

- Timoshenko, Stephen P. Vibration problems in engineering / 1928. (2236863)

- Braun, S. editor, Encyclopedia of vibration / editor- c2002. (2233503)

- Inmam, Daniel J. — 2nd ed. Engineering vibration / Daniel J. I c2001. (2231193)

Rotating Machinery

- Ehrich, Fredric F. editor, Handbook of rotordynamics / Fredric c1992. (2182308)

- Childs, Dara, Turbomachinery rotordynamics : phen c1993. (2140025)

- Lalanne, Michel, Rotordynamics prediction in enginee c1990. (2107920)

- Vance, John M. Rotordynamics of turbomachinery / J c1988. (2071065)

- Adams, Maurice L. Rotating machinery vibration : from c2001. (2225652)

- Wowk, Victor, Machinery vibration : balancing / V c1995. (2153552)

- Kramer, Erwin, Dynamics of rotors and foundations c1993. (2134324)

Free Rotor Dynamics MATLAB Toolbox

Description

RotFE is a suite of programs that allows one to model rotating shafts mounted on bearings and with disks and point masses. The programs were developed as a simple aid for research and Teaching (In: Imperial College London and Technion-Israel).

The program contains:

- Rotfe ? A bending vibration modeling program: Uses Timoshenko beam elements and includes gyroscopic effects (due to rotation). Also: Allows to model (i) anisotropic bearings (ii) misalignment (iii) rigid disks (damping) – this program uses a standard TEXT input file with geometry and material constants + boundary conditions.

- modeplot2 – Graphical user interface to visualize the response- computes critical speeds – computes modeshapes, forward/backward whirling.

- Campbell ? a program to compute the ‘campbell diagram’: visualize the effect of rotating speed on the natural frequencies.

- Rot2ss ? Create state-space model.

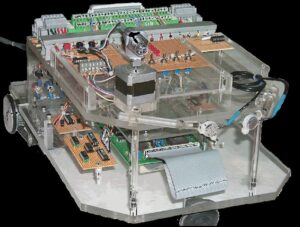

Microprocessor Based Product Design

Modern Mechanical engineers find themselves involved in multidisciplinary projects designing. Mechanical Engineers are expected to design smart, flexible, modifiable and inexpensive products. Some of the answers to these new demands are provided by a new design and thinking methodology called Mechatronics.New products combine sensors, motors and intelligence meaning a microprocessor.

Modern Mechanical engineers find themselves involved in multidisciplinary projects designing. Mechanical Engineers are expected to design smart, flexible, modifiable and inexpensive products. Some of the answers to these new demands are provided by a new design and thinking methodology called Mechatronics.New products combine sensors, motors and intelligence meaning a microprocessor.

In this course Students are being exposed to microprocessors in general and micocontrollers in particular. Microcontrollers are electronics creatures that have on a single piece of silicon both a computing engine (CPU) and some units that allow us to connect to external devices like sensors, motors etc.

![]() Sylabus

Sylabus

Course Topics

- Introduction, review and examples for the role of a microprocessor in new products.

- Programming the microprocessor (microcontroller) to handle electromechanical products incorporating sensors.

- Methods for interfacing the real world performing and input/ output: Polling and interrupts.

- Sensors actuators, design of integrated systems.

- Laboratory exercises on a real system controlled by a micro-computer (TMS320F240), motors, actuators, sensors.

- Programming the laboratory system using Assembly & C languages.

- Creating a man-machine interface, transferring data and commands to/from the system in real-time.

Grade Composition

- Introductory exercise – 3%

- 4 labs assignments – 40%

- 4 quizes – 32%

- Final Project – 25%

Lab Opening hours

- sun: 14:00-21:00

- mon: 14:00-21:00

- tue: 14:00-21:00

- wed: 14:00-21:00

- thu: 14:00-21:00

Final Project

- Instructions

Undergraduate Projects

The Dynamics Laboratory offers undergraduate students the opportunity to undertake their annual project as part of their academic requirements. The projects are multi-disciplinary, combining precision mechanical design, dynamics, electronics, real-time signal processing and control thus, providing the students with comprehensive knowledge and experience in theoretical and practical aspects of mechanical engineering.